Digitize your monitoring

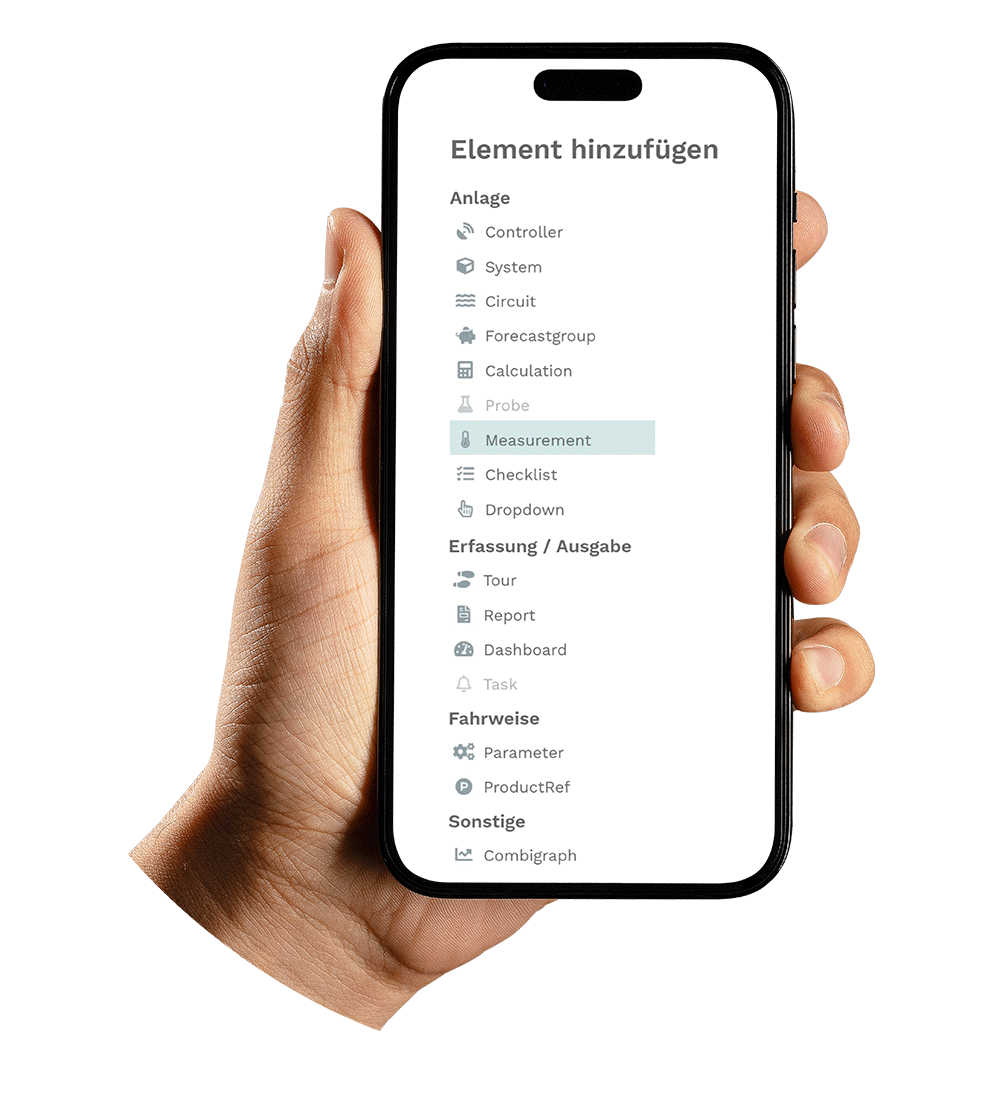

With SIUNIS, you can digitally record your entire industrial plant

-

Document, monitor, optimize

-

All data & measured values always at a glance

-

Statistics, trends & forecasts

-

Simple workflow & structured documentation

SIUNIS optimizes all requirements for modern monitoring

Discover untapped savings potential for your plants!

Optimize your system in 3 steps

Digitize quickly and easily now!

Step 1:

set up web app

Step 2:

Avoid downtimes & increase safety

Step 3:

Implement & document

Monitor your industrial plant

Select your plant type to find out more!

15 years

experience with digital operating logs

Pioneer

in the digitalization of cooling and boiler systems

50+ years

experience with cooling and boiler systems worldwide